G Codes For Mach3

So you’d like to play with G-Code but don’t have any sample g-code files?

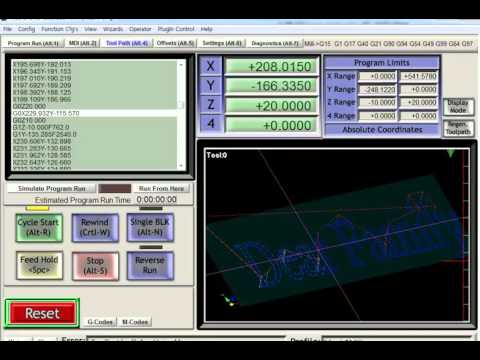

Nov 19, 2013 DXF to TAP and then to MACH3. This is the high resolution video of the older upload.

For starters, be sure to check out our Free G-Code Tutorial. It’s full of examples on a case-by-case basis.

Want completed programs?

No worries, here’s a bunch of examples:

G-Code Examples for Milling Machines

boomerangv4.ncc: 3D profiling job on a boomerang.

Griffin Relief.ncc: 3D profiling job for a gryphon logo.

HomeSwitchRearPanelEngrave: A control panel for my CNC electronics.

SupportLogo.ncc: CNCCookbook logo for my tooling rack.

G-Code Macro Examples

Warm Up Program: Runs your spindle and axes to warmup the CNC machine.

How do i turn off microsoft office updates on mac. Peck Drilling: Customize your peck cycle with this macro.

G-Code Examples for Each G-Code and M-Code

Our handy g-code reference lists have links to specific g-code examples for each g-code and m-code.

How about a Free G-Code Viewer? Check this out:

Create your own G-Code Examples with Conversational Programming

With Conversational Programming, it’s easy to create your own g-code examples…

Conversational Programming is a way to create simple g-code programs with CADCAM software. You simply answer questions in a simple Wizard format and it will generate the g-code for the operation. Our G-Wizard Editor Software has a free built-in Conversational Programming Module you can use to generate all sorts of g-code examples.

More G-Code Resources

Do You Have Some Cool G-Code?

We’re always on the lookout for cool g-code files to add to this page. If you have some you think is worthy, we’re interested. If we wind up adding it to this page for download, we’ll give you a free lifetime copy of our G-Wizard Editor.

Here’s the sort of thing we’re looking for:

- Quick fun projects someone could CNC in a weekend.

- Useful g-code utilities such as subprograms others may want to include in their own g-code.

- G-Code that demonstrates some clever technique others can learn from.

If you think you’ve got just the ticket, send me an email via bob@cnccookbook.com. Include your g-code, tell me what sort of control it runs on, what it is, and briefly say why you think it should be added to our g-code page. I’ll let you know quickly whether I’m going to add it and whether you get your free copy of G-Wizard Editor.

Cheers!

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!More articles you may like:

A list of g-codes and m-codes for milling in the Fanuc, LinuxCNC, GRBL, and Haas dialects. We give a quick definition of each g-code along with a link to tutorials and examples of how to use it. Click the g-code link (if any) to visit a tutorial from our popuplar Online Free G-Code Training that shows examples and teaches how to program CNC machines using the g-code.

Function | Notes | ||

| G00 | Move in a straight line at rapids speed. | XYZ of endpoint | |

| G01 | Motion | Move in a straight line at last speed commanded by a (F)eedrate | XYZ of endpoint |

| G02 | Clockwise circular arc at (F)eedrate | XYZ of endpoint IJK relative to center R for radius | |

| G03 | Motion | Counter-clockwise circular arc at (F)eedrate | XYZ of endpoint IJK relative to center R for radius |

| G04 | Dwell: Stop for a specified time. | P for milliseconds X for seconds | |

| G05 | Motion | FADAL Non-Modal Rapids | |

| G09 | Exact stop check | ||

| G10 | Compensation | Programmable parameter input | |

| G15 | Turn Polar Coordinates OFF, return to Cartesian Coordinates | ||

| G16 | Coordinate | Turn Polar Coordinates ON | |

| G17 | Select X-Y plane | ||

| G18 | Coordinate | Select X-Z plane | |

| G19 | Select Y-Z plane | ||

| G20 | Coordinate | Program coordinates are inches | |

| G21 | Program coordinates are mm | ||

| G27 | Motion | Reference point return check | |

| G28 | Return to home position | ||

| G29 | Motion | Return from the reference position | |

| G30 | Return to the 2nd, 3rd, and 4th reference point | ||

| G32 | Canned | Constant lead threading (like G01 synchronized with spindle) | |

| G40 | Tool cutter compensation off (radius comp.) | ||

| G41 | Compensation | Tool cutter compensation left (radius comp.) | |

| G42 | Tool cutter compensation right (radius comp.) | ||

| G43 | Compensation | Apply tool length compensation (plus) | |

| G44 | Apply tool length compensation (minus) | ||

| G49 | Compensation | Tool length compensation cancel | |

| G50 | Reset all scale factors to 1.0 | ||

| G51 | Compensation | Turn on scale factors | |

| G52 | Local workshift for all coordinate systems: add XYZ offsets | ||

| G53 | Machine coordinate system (cancel work offsets) | ||

| G54 | Work coordinate system (1st Workpiece) | ||

| G55 | Work coordinate system (2nd Workpiece) | ||

| G56 | Work coordinate system (3rd Workpiece) | ||

| G57 | Work coordinate system (4th Workpiece) | ||

| G58 | Work coordinate system (5th Workpiece) | ||

| G59 | Work coordinate system (6th Workpiece) | ||

| G61 | Other | Exact stop check mode | |

| G62 | Automatic corner override | ||

| G63 | Other | Tapping mode | |

| G64 | Best speed path | ||

| G65 | Other | Custom macro simple call | |

| G68 | Coordinate System Rotation | ||

| G69 | Coordinate | Cancel Coordinate System Rotation | |

| G73 | High speed drilling cycle (small retract) | ||

| G74 | Canned | Left hand tapping cycle | |

| G76 | Fine boring cyle | ||

| G80 | Canned | Cancel canned cycle | |

| G81 | Simple drilling cycle | ||

| G82 | Canned | Drilling cycle with dwell (counterboring) | |

| G83 | Peck drilling cycle (full retract) | ||

| G84 | Canned | Tapping cycle | |

| G85 | Boring canned cycle, no dwell, feed out | ||

| G86 | Canned | Boring canned cycle, spindle stop, rapid out | |

| G87 | Back boring canned cycle | ||

| G88 | Canned | Boring canned cycle, spindle stop, manual out | |

| G89 | Boring canned cycle, dwell, feed out | ||

| G90 | Absolute programming of XYZ (type B and C systems) | ||

| G90.1 | Absolute programming IJK (type B and C systems) | ||

| G91 | Incremental programming of XYZ (type B and C systems) | ||

| G91.1 | Incremental programming IJK (type B and C systems) | ||

| G92 | Offset coordinate system and save parameters | ||

| G92 (alternate) | Motion | Clamp of maximum spindle speed | S |

| G92.1 | Cancel offset and zero parameters | ||

| G92.2 | Cancel offset and retain parameters | ||

| G92.3 | Offset coordinate system with saved parameters | ||

| G94 | Motion | Units per minute feed mode. Units in inches or mm. | |

| G95 | Units per revolution feed mode. Units in inches or mm. | ||

| G96 | Motion | Constant surface speed | |

| G97 | Cancel constant surface speed | ||

| G98 | Canned | Return to initial Z plane after canned cycle | |

| G99 | Return to initial R plane after canned cycle |

Get a Powerful G-Code Simulator and Editor to Simplify G-Code Work

Function | Notes | |

| M00 | Program Stop (non-optional) | |

| M01 | M-Code | Optional Stop: Operator Selected to Enable |

| M02 | End of Program | |

| M03 | M-Code | Spindle ON (CW Rotation) |

| M04 | Spindle ON (CCW Rotation) | |

| M05 | M-Code | Spindle Stop |

| M06 | Tool Change | |

| M07 | M-Code | Mist Coolant ON |

| M08 | Flood Coolant ON | |

| M09 | M-Code | Coolant OFF |

| M17 | FADAL subroutine return | |

| M29 | M-Code | Rigid Tapping Mode on Fanuc Controls |

| M30 | End of Program, Rewind and Reset Modes | |

| M97 | M-Code | Haas-Style Subprogram Call |

| M98 | Subprogram Call | |

| M99 | M-Code | Return from Subprogram |

Bonus: Check Out our Other CNC Cookbooks for More In-Depth CNC Information!

If you’re a CNC Beginnner, check out our CNC Beginner’s Cookbook. It’ll get you up to speed with a solid CNC foundation fast. Download flash update for mac download.

We also have Cookbooks for Feeds and Speeds, G-Code Programming, CNC Manufacturing and Shop Management, DIY CNC, and don’t forget the CNC Cookbook Blog–with over 4 million visitors a year it’s the most popular CNC blog by far on the web.

More Resources